Double acting hydraulic cylinder for baler

Double Acting Hydraulic Cylinder for Baler

Some custom hydraulic cylinders have flexible bearings on them. Due to the sturdy and flexible bearings, you can quickly fix and install the cylinder on your tractors or mini excavators. It is durable enough to hold a lot of force.The top link cylinder is built under specific dimensions. The parameters of cylinders are as followed:

- Bore: 20mm-600mm.

- Stroke Length: 10mm-1000mm.

- Seals kit: DLI,HALLITE and PARKER.

- Working pressure:low or medium

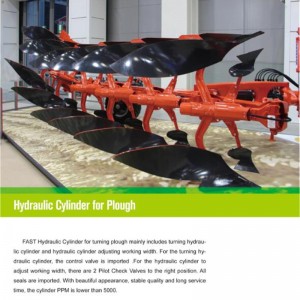

The well-assembled and thoroughly tested double acting hydraulic cylinder for baler also adopt a double pilot operated check valve to hold the cylinder steady and prevent it from drifting away. The assembled inside sealing rings guard the high performance of sealing, making it easier to maintain and safer to use.The double acting hydraulic cylinder for baler is environmental protection equipment that compresses straws into blocks with hydraulic power, making the straw blocks easier to store, transport and utilize.

FAST got 15 production lines with 1 telescopic cylinder production line included.Our annual productivity of hydraulic cylinder has reached 400,000pcs. The common producing period of each item is approximately 30 days, which would be varied according to specific products.

Competitive Advantages

High Qualities: Cylinder body and piston are made from solid chrome steel and heat-treated.

Great Durability: Hard-chromium plated piston with replaceable, heat treated saddle.

Stronger Mechanical Strength: Stop ring can bear full capacity (pressure) and is fitted with dirt wiper.

Corrosion Resistant: Perfectly passed the neutral salt spray test (NSS) Grade 9/96 hours.

Long life span: FAST cylinders have passed over 200,000 cycles cylinder life test.

Cleanliness: Through fine cleaning, surface detection, ultrasonic cleaning and dust-free transfer during the process, and laboratory test and real-time cleanliness detection after assembly, FAST cylinders have reached Grade 8 of NAS1638.

Strict Quality control: PPM lower than 5000

Considerate Services

Sample Service: Samples will be provided according to customer's instruction.

Customized Services: A variety of cylinders can be customized according to customer demand.

Warranty Service: In case of quality problems under 1 year warranty period, free replacement will be made for customer.

Company Profile

|

Establish Year |

1973 |

|

Factories |

3 factories |

|

Staff |

500 employees including 60 engineers,30 QC staff |

|

Production Line |

13 lines |

|

Yearly Production Capability |

Hydraulic Cylinders 450,000 sets; Hydraulic System 2000 sets. |

|

Sales Amount |

USD45 Million |

|

Main Export Countries |

America,Sweden,Russian,Australia |

|

Quality System |

ISO9001 |

|

Patents |

89 patents |

|

Guarantee |

13 months |