Here we mainly listed the below 3 broken situations-Bush Broken or Rod Eye Broken or other Mount Connection Failure; Rod Weld fracture and Rod broken.

1. Bush Broken, Rod Eye Broken,or other Mount Connection Failure

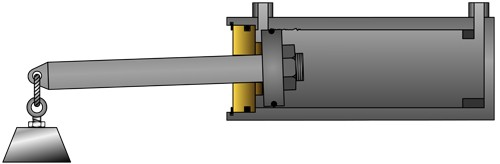

A cylinder is mounted through various methods: rod or barrel eyes, trunnion, flange, and more. When a cylinder is over-loaded or misaligned, excessive stress is applied to the mounting connection which results in faster wear or even failure. Rod eye bushings and bearings can become worn, chipped, or broken creating slop and undesirable movement.

2. Rod Weld fracture

a.Welding failure

Effective melting length and depth of fusion are not qualified. As the picture shows-Effective melting length is 4mm and the Depth of fusion with base material is <0.5mm

b.Weld Crack In the welding process or after welding, metal rupture in the welding area, it arises inside or outside the weld, may also occur in the heat-affected zone

c. Wrong welding current, if the current is too small, the arc is not stable, easy to cause slag inclusions and unwelded defects, and low productivity; If the current is too much, easy to bite burn, and other defects, while increasing spatter.

d. Improper use of materials, such as piston rod (material 45Mn) and forkhead (material 42CrMo) consisting of welded parts. Base material: piston rod material 45Mn carbon equivalent Ceq = 0.735%, 42CrMo carbon equivalent Ceq = 0.825%, weldability are very poor, at room temperature welding is very easy to produce hardened tissue, so that the weld tissue plasticity and toughness decline, poor crack resistance.

3. Rod broken

Material strength is not enough; Structure problem; Welding Problem

For more information about hydraulic cylinder design or repair, please just feel free to contact lily by WhatsApp or Wechat at 8613964561246.

Post time: Dec-09-2022