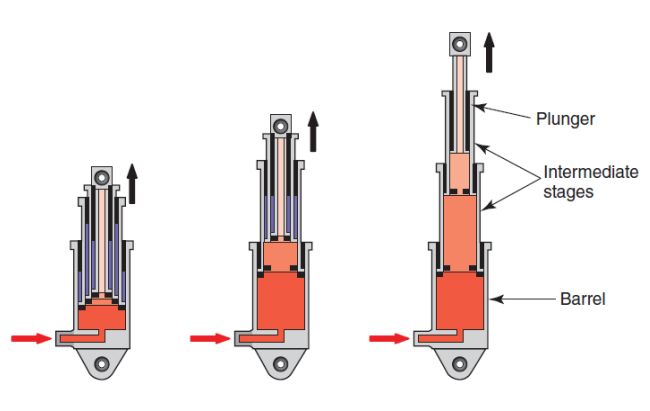

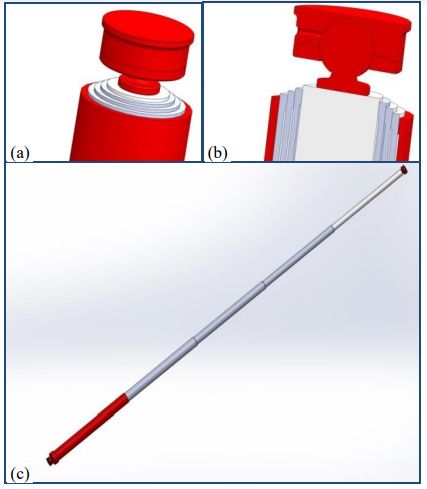

A.Missed stages of telescopic cylinders

1) There are several reasons that the dump truck cylinder may be missing stages of the extension or retraction operation. For example, the largest sleeve extends properly, but the plunger starts extending before the middle (or next larger) sleeve starts to extend. The middle sleeve finally breaks loose and shoots out, causing it and the plunger to collapse or drop back into the cylinder. This creates a loud banging noise as the dump truck cylinder slams down.

2) The main reasons are related to the size accuracy, straightness, roundness of the cylinder barrel and piston rod, and overall matching of the sealing system. The roundness of raw material, machine tool accuracy, jig error, tool vibration, and other factors. The above factors lead to the L-shaped support ring of the upper cylinder and the lower piston rod being too tight and the surface friction being too large when the hydraulic cylinder extends and retracts. And The Cylinder that the body or unit is mounted in may have a worn or damaged part. This causes the cylinder to sideload, not allowing the sleeve to extend or retract in the correct order.

B.Telescopic cylinder jam, excessive expansion due to high temperature

1) Usually for garbage trucks telescopic cylinders. A certain stage of barrel expansion resulted in the cylinder being scrapped.

2) The main reason- Missed stage situation caused instantly high oil pressure, which exceed the yield strength of the barrel material and caused a damaged barrel.

3) Solutions-Firstly solve missed stage situation, then control the working pressure.

For more information about hydraulic cylinder design or repair, please just feel free to contact us by sales@fasthydraulic.com

Post time: Nov-24-2022